Omani upstream energy firm ARA Petroleum says it has teamed upwith Austrian solar engineering specialist Heliovis to set up what isbilled as the world’s first solar-thermally powered, zero emission waterdesalination plant in the Sultanate of Oman.

Unlike conventional water desalination plants – solar powered orotherwise – which use seawater or brackish water as feed forprocessing, the first-of-its-kind Oman project will treat produced water– naturally occurring water in oil reservoirs that is produced along withhydrocarbons. Their high concentration of mineral salts, heavy metalsand hydrocarbon contaminants necessitate their safe disposal eitherin deep aquifers or carefully managed evaporation ponds.

According to ARA Petroleum, a subsidiary of Zubair Group, the modest-sized plant, with a capacity of 140 cubic metres/day, will be set up inQarat al Milh, a small oilfield that forms part of the Block 6 license ofPetroleum Development Oman (PDO). ARA Petroleum operates the1,528 sq kilometre oilfield as part of a contract with PDO.

A commercial contract signed with Vienna-based Heliovis will enableARA Petroleum to harness the latter’s patented and proven low-costsolar thermal technology to treat highly saline oil-contaminatedproduced water into drinking water – a first for Oman on a commercialscale.

The solar thermal energy will be harnessed to power a forwardosmosis (FO) water desalination plant to transform produced water,which is three-times more salty than seawater, into potable water ofdrinking quality.

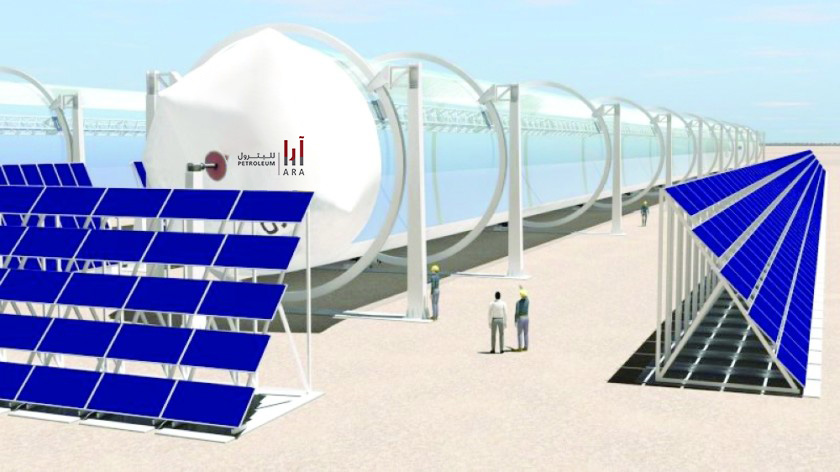

Heliovis plans to deploy its proprietary HELIOtube technology thatutilises recyclable inflatable tubes and mirror films to collect andconcentrate sunlight to generate emission-free industrial process heat.

“The technology gives major cost advantages in manufacturing,shipping/logistics, installation, cleaning, maintenance, and freshwaterusage compared to conventional parabolic troughs that employ bentglass mirrors. In the context of the oil & gas industry, it can be usedamongst others to power refineries and gas scrubbing facilities, togenerate steam for enhanced oil recovery (EOR), or to desalinateproduced water as in the present case,” according to the Austriancompany.

Felix Tiefenbacher, CEO of Heliovis, commented, “We are lookingforward to building on our success with a next generation solarthermal desalination project in Oman. This collaboration with ARAPetroleum demonstrates the scale of opportunity for our unique, low-cost technology to decarbonise industrial heat, including for oil & gasoperations. We are pleased to be working with ARA Petroleum to growOman’s solar industry and the global market for zero emissiondesalination.”

Dr Omar al Jaaidi , General Manager of ARA Petroleum Exploration &Production, said, “We are excited about working with Heliovis toenhance our environmental stewardship in Oman and strengthenARA’s position in the lower-carbon economy. This is a strategicopportunity for us to tap into solar as a sustainable source of energy inorder to minimise the carbon footprint of our operations.”